When it comes to HVAC and plumbing systems, the right insulation thickness can determine whether the installation is efficient or if it wastes energy and raises maintenance costs. Choosing the right thickness helps control heat transfer, reduces condensation, and extends the life of piping systems. For contractors, knowing these factors ensures that each project meets energy efficiency goals, safety requirements, and long-term performance needs.

Why Pipe Insulation Thickness Matters

The thickness of insulation directly affects how well a system saves energy. It reduces heat loss in hot water lines and stops condensation on cold water pipes, which can cause corrosion or water damage. Proper insulation also cuts down noise, improves fire safety, and helps the overall efficiency of the system. In commercial projects, it can greatly reduce operational costs and boost building sustainability ratings.

Key Factors in Choosing the Right Thickness

Several elements influence the correct insulation thickness for any installation.

- Pipe size and material: Metal pipes need thicker insulation because they conduct heat better.

- Operating temperature: Higher or lower temperatures require extra insulation layers for safety and performance.

- Environmental exposure: Outdoor, underground, or humid environments require moisture-resistant insulation.

- Building type and regulations: Residential, commercial, and industrial projects follow specific thermal and acoustic requirements.

Balancing these factors ensures durable, compliant, and efficient results.

Australian Standards and Compliance

Contractors should refer to AS/NZS 4859.1 and AS/NZS 1530.3, which set the standards for insulation’s thermal and fire performance. Following these standards is not just about meeting requirements; it is about ensuring consistent quality, safety, and reliability in all installations. Using certified products also improves project credibility and reduces liability risks.

Common Thickness Recommendations

Insulation thickness usually varies from 13mm for domestic hot water lines to over 40mm for chilled or industrial systems. The right thickness depends on the pipe diameter, temperature range, and surrounding conditions. Always check the manufacturer’s data sheets to make sure the chosen material meets performance needs and project specifications.

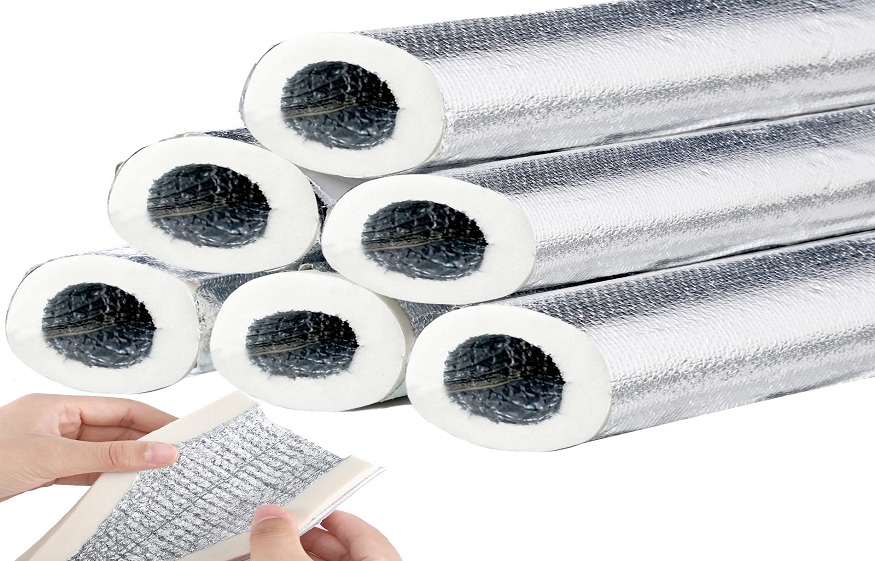

Performance Features of Modern Pipe Insulation

Modern insulation materials are engineered for durability, safety, and energy savings. Closed-cell, pre-formed foam offers excellent thermal protection. Reinforced aluminum foil improves heat resistance. These materials resist moisture, are anti-microbial, and work well for underground installations. Many are eco-friendly, with low VOC emissions, no ozone-depleting substances, and up to 50% recycled content.

One notable option is the Thermotec 4-Zero Thermal Wrap. This Australian-made insulation focuses on maximum energy efficiency and safety. It features high-density foam for durability, non-toxic fume performance, and quick installation with its pre-slit, factory-fitted design; this makes it a great choice for modern sustainable construction.

Installation Tips for Optimal Performance

For the best results, clean and dry pipes before installation. Avoid compressing the insulation because this can reduce its thermal effectiveness. Seal all joints tightly to prevent moisture from getting in. Use vapor barriers or cladding for outdoor or exposed areas. Following these steps ensures consistent insulation performance and protects the system.

Cost vs. Efficiency Considerations

Thicker insulation might raise initial costs, but it provides lasting value through energy savings, less heat loss, and fewer maintenance problems. Contractors can point out these benefits to clients as a wise investment that brings returns over time. Using high-quality materials also lowers the chance of early wear, ensuring dependable performance for years.

Conclusion

Selecting the right pipe insulation thickness is important for creating efficient, safe, and sustainable piping systems. By looking at environmental factors, compliance standards, and material quality, contractors can ensure the best performance and energy savings. Products like the Thermotec 4-Zero Thermal Wrap demonstrate how improvements in insulation technology are pushing Australia’s construction industry towards greener and more efficient solutions.